Via Nicola Persico, 9 - 23

Gioia del Colle (BA), Italy

Via Giosuè Carducci, 23

Cortenuova (BG), Italy

Export Dpt.

+39 340 846 7264

Gioia del Colle (BA), Italy

Cortenuova (BG), Italy

+39 340 846 7264

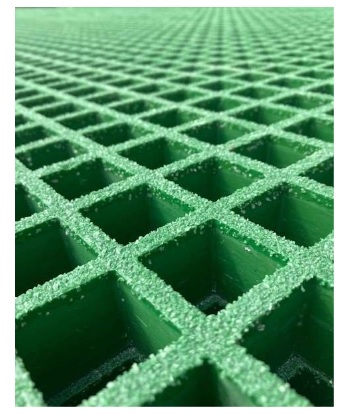

GRP gratings are particularly suitable for use in the presence of chemicals and in corrosive environments. They are non-magnetic and have high resistance to acids, UV radiation and fire. They are used for the construction of walkways, stairs, platforms, ventilation gratings, fences, and in many other applications where a surface resistant to corrosive liquids is required.

This type of grating, more commonly known as fibreglass grating, does not need surface treatments such as painting or galvanising, is lightweight, easy to install and requires minimal maintenance. The panels can be cut or drilled directly on site using the most common cutting tools. Thanks to their mechanical, physical and chemical properties, they have become an integral part of the construction and industrial sectors, offering an optimal combination of strength, durability and lightness.

Flame Spread /Smoke Developed Index in accordance to

ASTM E-84 CLASS 20 (A)

Fill the form to receive the EmmeGi Catalog in PDF directly to your email address, future updates on products and news.

EMMEGI Spa is a leading Italian company specialising in the production and marketing of open mesh press-welded grating, metal fences, CE-marked gates, metal stair treads and safety ladders, active in the domestic and international market